NVIDIA Empowers Foxlink Robots to Drive Smart Security Systems and Digital Transformation in Advanced Manufacturing

NVIDIA Empowers Foxlink Robots to Drive Smart Security Systems and Digital Transformation in Advanced Manufacturing

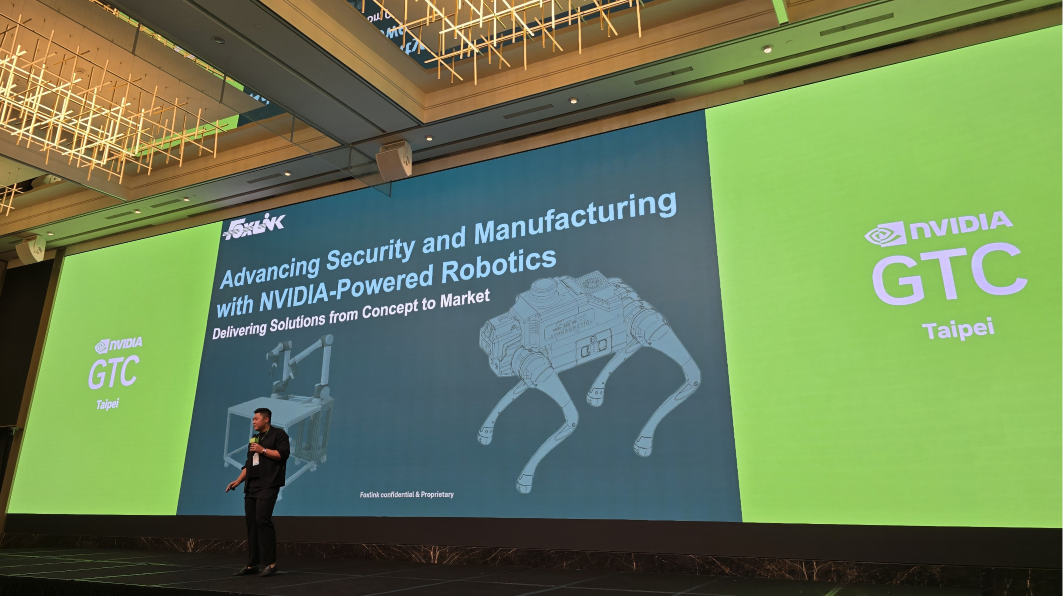

On May 22, 2025, Foxlink Group made a strong presence at the NVIDIA GTC Taipei, where Special Assistant to the Group Chairman, Mr. Shou-Fu Kuo, and Head of Robotics R&D, Mr. Sean Zhan, delivered a keynote presentation highlighting Foxlink’s latest innovations in AI-powered robotics. Centered on the theme “Robotics Technology Development and Innovation,” the presentation showcased how Foxlink is leveraging NVIDIA’s comprehensive technology ecosystem to accelerate digital transformation in smart security and advanced manufacturing.

The highlight of this year’s presentation was Foxlink’s integrated robotics platform, featuring two core applications. These include the AI robotic security solution jointly developed by SYNC ROBOTIC, a Foxlink Group company, and Luminys, as well as a dual-arm dexterous robotic system deployed in manufacturing environments.

The AI security robot solution integrates a suite of NVIDIA technologies—including Jetson AGX Orin™, Isaac™ Sim, TensorRT™, Metropolis, X-Mobility, and RIVA—to enable advanced features such as facial recognition, license plate identification, autonomous navigation, voice interaction, and automatic charging. Through a Sim2Real training pipeline, the platform enables rapid iteration from virtual simulation to real-world deployment.

Luminys’ real-time video analytics and intelligent surveillance platform ensures seamless integration of the security robot into enterprise environments, enhancing risk awareness and response capabilities. This end-to-end AI solution is designed for deployment across factories, energy sites, and commercial buildings, providing comprehensive and intelligent site protection.

The dual-arm dexterous robotic system is built on the NVIDIA Isaac GR00T N1 architecture and integrates a vision-language multimodal model. This enables the robot to interpret semantic commands and combine visual recognition with real-time robotic state data to autonomously perform tasks such as “pick up the battery and place it in the battery holder.”

Initial training is conducted in simulation using Isaac Sim, followed by real-world data collection from physical robot demonstrations. The system leverages motion trajectory data for fine-tuning through imitation learning, significantly enhancing operational precision and adaptability.

This solution has already been successfully deployed in Foxlink’s factory for battery cell arrangement tasks. It supports flexible production requirements with small-batch, high-mix operations, improving collaboration between human operators and robotic systems in terms of both efficiency and accuracy.

With AI as its core driving force, Foxlink Group has joined forces with NVIDIA to pioneer next-generation robotics and intelligent applications—setting a new benchmark for global innovation in smart manufacturing and security.