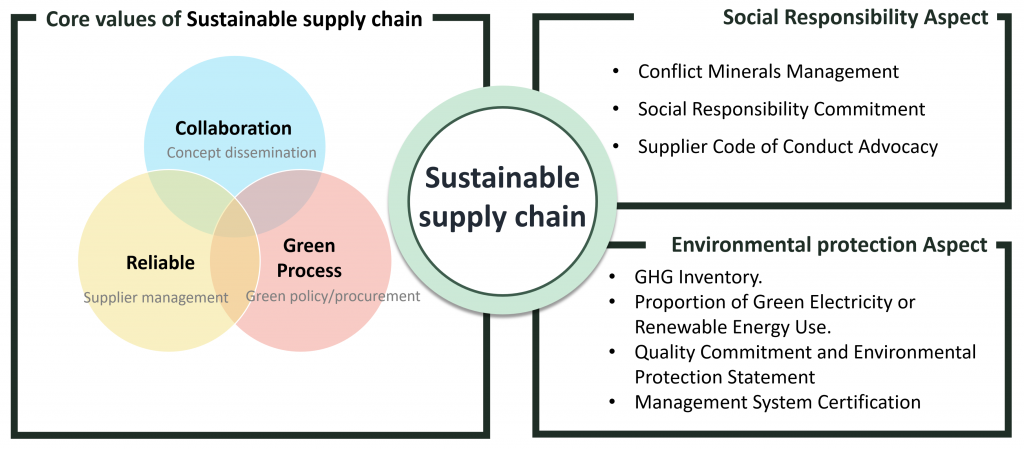

Sustainable supply chain and Supplier Management

FOXLINK’s sustainable supply chain focuses on digital collaboration, compliance reliability, and green procurement as its primary core execution areas. The goal is to reduce environmental and social impacts throughout the supply chain process. Evaluation and auditing of supplier qualifications emphasize environmental and social aspects. The Company uses its influence to advocate energy reduction, water conservation, and waste reduction goals to supplier partners, aligning them with sustainable development objectives. This approach aims to minimize environmental and social conflicts while enhancing supplier management effectiveness and fostering positive supplier relationships.

FOXLINK establishes the Supplier Code of Conduct based on the Responsible Business Alliance (RBA) Code of Conduct, and sends it to suppliers. Suppliers are required to understand and comply with the following:

- RBA Code of Conduct: Suppliers must respect labor rights, ensure occupational health and safety, take environmental responsibility, adhere to the highest ethical standards, and establish management systems.

- Responsible Procurement: Suppliers commit to not using conflict minerals.

- Green Product Management: Suppliers must sign the Environmental Protection Statement and quality commitments to ensure compliance with hazardous substance management requirements throughout their processes.

- CSR Corporate Social Responsibility Compliance: FOXLINK collects supplier risks, conducts on-site audits, and implements improvements and process optimizations.

- Restriction of Hazardous Substances (RoHS): Implementation covers raw materials, processes, and finished products to ensure all products meet green product requirements and customer demands, reducing environmental impact.

- All manufacturers must be ISO9001 and ISO14001 certified. Additionally, all material suppliers are required to submit commitment documents related to environmental and social aspects. These documents include environmental commitments, quality commitments, occupational health and safety declarations, social responsibility commitments, and conflict-free mineral commitments.

Supplier Code of Conduct

In order to strengthen the commitment to sustainability within its supply chain, FOXLINK references the RBA Code of Conduct, focusing on five key areas: labor, health and safety, environment, ethics, and management systems. Aligning with the Group’s operational philosophy of “sincerity, macro perspective, and responsibility”, FOXLINK has formulated the “FOXLINK Supplier Social Responsibility Code of Conduct”. This aims to leverage the Group’s influence to require suppliers to comply with all applicable laws and regulations of their operating countries/regions, ensuring a healthy and safe working environment for employees, respecting human rights, and undertaking environmental responsibilities and ethical standards in their operations. FOXLINK requires suppliers to adhere to these standards as a prerequisite for collaboration and encourages them to adopt internationally recognized industry standards and initiatives to continuously enhance their social responsibility management practices. Additionally, suppliers are obligated to communicate and implement these requirements with their downstream suppliers. FOXLINK prohibits suppliers from engaging in the following six “core non-compliance” areas:

- Use of child labor.

- Use of forced labor/prison labor.

- Existence of health and safety issues that immediately endanger employees’ lives or cause serious injury.

- Significant environmental impact or pollution.

- Providing false information;

- Bribery.

Responsible Procurement

For mineral procurement, suppliers should follow the steps outlined in the OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas (“OECD Due Diligence Guidance”).

Suppliers should require smelters, refiners, and mineral processing plants in their supply chains to participate in the Responsible Minerals Initiative (RMI) and undergo the Responsible Minerals Assurance Process (RMAP) or an equivalent smelter validation program recognized as compliant with the OECD Due Diligence Guidance, ensuring they meet RMAP or equivalent standards.

Suppliers should adopt Foxlink’s raw material procurement policy and commit to conducting due diligence. The scope of specific raw materials should include tantalum, tin, tungsten, gold (collectively known as “3TG”), mica, cobalt, and other minerals prioritized by specific customers.

If any smelters or refiners are found not to have passed the RMAP certification or do not meet customer requirements, suppliers are required to submit a removal plan or be removed from the supply chain within the specified timeframe.

This ensures that procurement sources from suppliers do not originate from conflict-affected or high-risk areas and comply with customer and regulatory requirements.